Patent Filing Details Unique 7000 Series Aluminum Used in iPhone 6s

An Apple patent filing titled “7XXX Series Alloy with Cu Having High Yield Strength and Improved Extrudability” uncovered by PatentlyApple, details the unique composition of the 7000 series aluminum alloy used in the new iPhone 6s / 6s Plus devices. It seems that the aerospace industry grade alloy used by Apple contains copper, features a higher yield strength and has extrusion speeds more rapid than conventional 7000 series Al alloys.

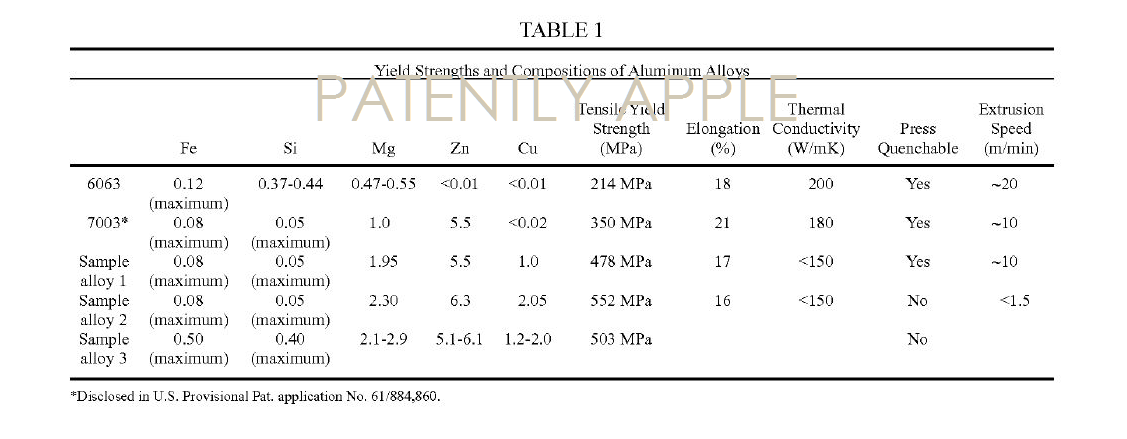

The above table shows the compositions, elemental compositions, yield strength, press quenchability, and extrusion speeds for examples of alloys and aluminum alloys. Sample alloys 1, 2, and 3 have various amounts of elements including Fe, Si, Mg, Zn, Cu, and Al, along with an increased tensile strength of at least 450 MPa. Comparative alloys 6063 and 7003 have lower tensile yield strength than the presently disclosed alloys. Sample alloys 1-3 have a yellow color due to the presence of Cu. Apple says that the amount of Cu can be altered to match a desired dye color.

“In some embodiments, the present alloys can be anodized. Anodizing is a surface treatment process for metal, most commonly used to protect aluminum alloys. Anodizing uses electrolytic passivation to increase the thickness of the natural oxide layer on the surface of metal parts. Anodizing may increase corrosion resistance and wear resistance, and may also provide better adhesion for paint primers and glues than bare metal. Anodized films may also be used for cosmetic effects, for example, it may add interference effects to reflected light”.

Apple’s patent application was originally filed in June 2015.