Apple: How to Make Your Own Face Shield to Protect Against COVID-19

Earlier this month, Apple announced it was designing face shields for health care workers to protect against COVID-19, at the rate of 1 million per week. After sharing instructions on how to assemble an Apple face shield, the company recently released a guide on how companies can make their own.

“These manufacturing instructions should only be used by an expert. Manufacturing the face shields requires professional level expertise in manufacturing and design, and should only be done by professional engineers or machinists in a factory environment,” explains the Apple document.

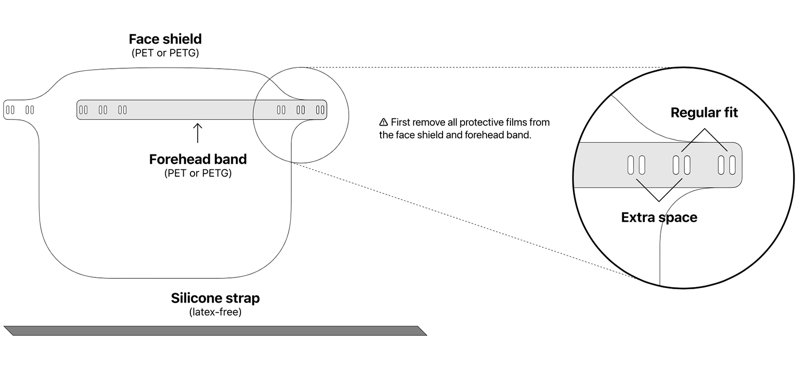

For the shield and forehead band, Apple recommends clear polyethylene terephthalate (PET) or polyethylene terephthalate glycol-modified (PETG) at 0.50mm thickness.

For the strap, Apple says you should use latex-free silicone (for no allergic reactions) at 1.4 to 1.6mm thickness and Shore 50A hardness.

Apple says die cutting has the highest throughput but investment is required, while water jetting is also advantageous over laser cutting. The company details the full face shield process in design files, 2D cut files, manufacturing drawings and instructions.

“If you need additional assistance with the fabrication of your face shield, please email faceshieldmake@apple.com,” says Apple.