First Look: Apple’s New Sapphire Factory, Plus How These Screens Are Made

GT Advanced announced yesterday that it will employ 700 people in a new Apple facility in Mesa, Arizona, where GT will make sapphire glass. The deal — which involves a $578-million advance payment from Apple toward GT – has drawn praise from Governor Jan Brewer and from a variety of Arizona officials.

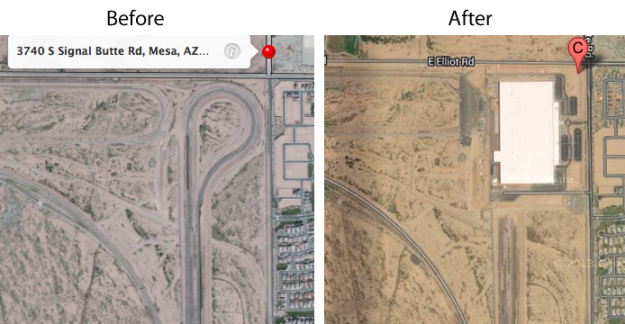

It turns out, the property belonged to First Solar, a Tempe-based manufacturer of thin-film solar cells, which built a facility in Mesa but never actually occupied it. Because First Solar scaled back its global expansion last year, it was seeking a tenant for the facility.

The Mesa facility ended up being sold last month to an unknown buyer for $100 million, says Fortune’s Philip Elmer-DeWitt. Although AZ Central has no information about the sale price, they just note that the building was sold at a $56-million loss.

As we found out yesterday via the press releases issued by GT and the State of Arizona, Apple is the new owner of the facility. Apple and GT have signed a contract, according to which the latter will own and operate furnaces and related equipment at the facility.

But how are sapphire displays made, and what can we expect from Apple’s new facility? MacRumors points to an April Pocketnow report, which presents the sapphire display manufacturing process. We don’t exactly know what Apple will use the sapphire for — except to protect the iDevice’s camera and Touch ID — but, according to MacRumors, an iWatch seems likely, as multiple luxury watch manufacturers use sapphire glass due to its durability.