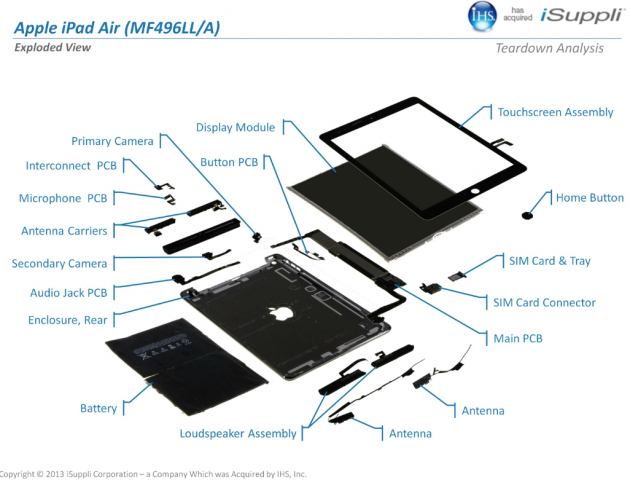

Teardown Analysis Estimates 16GB Wi-Fi iPad Air Costs $274 to Manufacture

The iPad Air launched just a couple days ago and the early adoption rate suggests it already has conquered the heart of new users, as this year five times more people lined up during the first weekend to shell out at least $499 compared to last year. But how much does it cost to manufacture?

We have already seen the iPad Air taken to pieces by iFixit and Chipworks, which perform their usual teardown analysis, but IHS Suppli isn’t far behind them with its usual teardown of Apple’s latest iDevice. And what IHS Suppli has found is indeed interesting: the iPad Air sports a more efficient Retina display than the previous generation, technology which actually cheaper is than the previous one.

In a report sent to AllThingsD, IHS Suppli reveals that the biggest change compared to the previous generation iPad was with the display and touchscreen assembly: it’s thinner and has fewer layers and fewer LEDs across the entire display. This helped Apple cut down on the weight, and save energy. The assembly, however, is more expensive than before, with the BOM being $133 — $90 for the display and $43 for the touchscreen parts.

After going through all components, IHS Suppli has found that the iPad Air costs between $274 and $361 to manufacture, depending on the model. The entry level iPad sells for $499, while the high-end model retails for $929.

Despite increasing the cost of the display assembly, the iPad Air is still $42 cheaper to build than the iPad 3.